Gear Manufacturing Expertise and Process Overview #

At Shyi Chang, we are dedicated to delivering precision gear solutions through a comprehensive suite of machining and inspection processes. Our capabilities span the full spectrum of gear production, from initial shaping to final quality assurance. Below, we outline the key processes and technologies that form the backbone of our manufacturing operations.

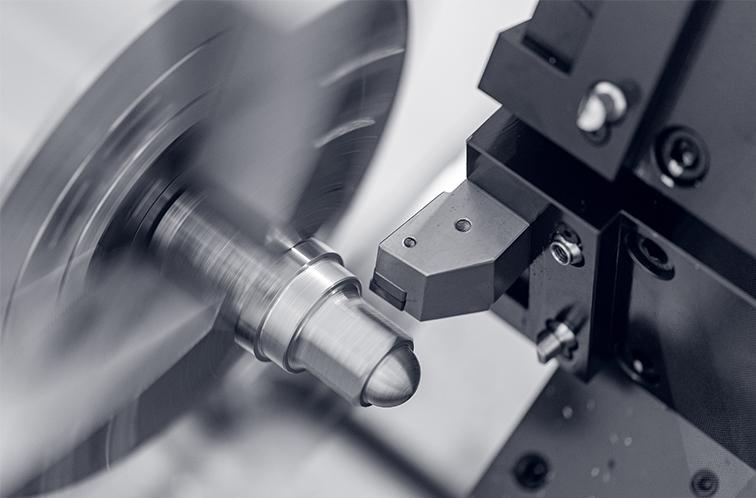

Lathes and Milling Machines #

Lathes are essential for metalworking, particularly for machining rotating workpieces. By securing the workpiece to the spindle, tools move along its length or circumference to remove excess material. This method is ideal for producing cylindrical, conical, and complex shapes, offering high efficiency and repeatability—making it well-suited for mass production.

Milling machines, on the other hand, are primarily used for cutting flat surfaces, grooves, profiles, and irregular shapes. Utilizing rotating cutters that move along the workpiece, milling machines can operate in both vertical and horizontal orientations. They are highly effective for manufacturing gears, gear racks, and intricate components.

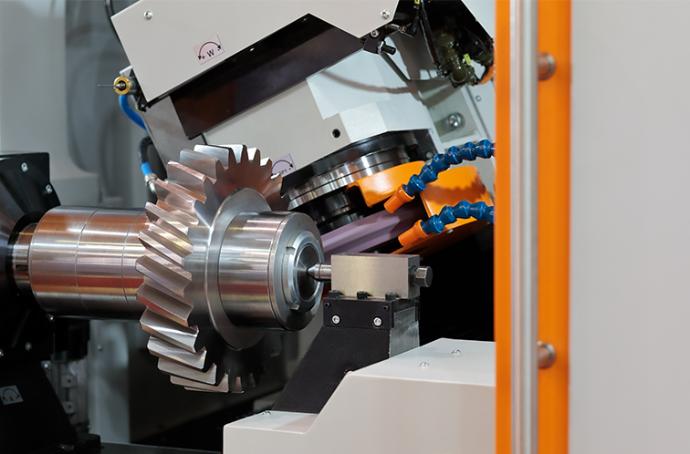

Hobbing and Shaping #

Hobbing is a specialized technique for gear manufacturing. Using a hobbing machine and a cutting tool called a hob, the tooth profile is cut into the gear. This process is ideal for producing large quantities of standard-sized gears, ensuring consistent cutting speed and tooth shape—making it a mainstream method in gear production.

Shaping is commonly used for gears with internal grooves or specific tooth profiles. A shaping machine employs specially designed tools (such as shaper cutters) to cut the workpiece, enabling the creation of unique tooth profiles and the machining of various workpiece types.

Broaching #

Broaching is used for machining specific shapes or sizes of holes and grooves, such as keyways and bolt holes. A shaper, equipped with a single cutting tool, moves along a return path to process longer workpieces. This method excels at achieving precise internal shapes without altering the overall workpiece geometry.

Grinding #

Grinding is a high-precision metalworking process that enhances surface finish and dimensional accuracy. Abrasive materials are pressed against the workpiece to remove material and achieve the desired smoothness. Grinding can be categorized as follows:

- Surface Grinding: Ensures flatness of material surfaces.

- Outer Diameter Grinding: Improves the accuracy of the outer circumference of circular workpieces.

- Gear Grinding: Refines the external tooth profile of gears for smooth engagement and noise reduction.

- Inner Hole Grinding: Enhances the dimensional accuracy and smoothness of internal holes, suitable for components requiring precise fitting.

Wire EDM (Electrical Discharge Machining) #

Wire EDM utilizes electrical discharge to cut metal with a thin, high-frequency moving wire (the electrode). This process is particularly effective for cutting complex shapes and thick metal workpieces, ensuring high-precision edges. Wire EDM is widely used in mold manufacturing, electronic components, and the processing of high-strength materials.

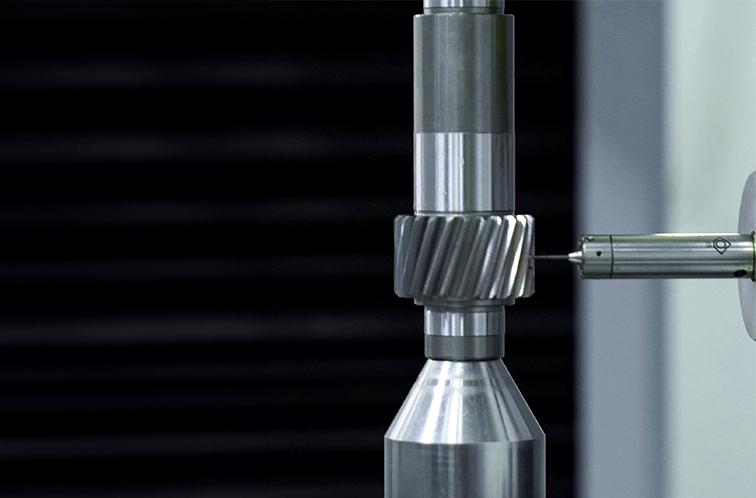

Finished Product Inspection #

Quality assurance is integral to our process. Finished product inspection covers appearance, dimensions, tooth profile, tooth shape, and gear accuracy. This ensures that every gear meets stringent standards before delivery.

Processing Material Solutions #

We offer a diverse range of material solutions to meet various application needs. Explore our material categories:

Processing Material Solutions

Processing Material Solutions Alloy Steel

Alloy Steel Carbon Steel

Carbon Steel Stainless Steel

Stainless Steel Special Purpose Steel

Special Purpose Steel Cast Iron

Cast Iron Copper and Copper Alloys

Copper and Copper Alloys Engineering Plastics

Engineering Plastics